Engineering colleges in India play a significant role in the growth of the Indian industry and economy. Among graduate engineers, those with exposure to shop floor operations like welding, and post-graduate engineers with welding as specialization are in great demand across industry sectors. That said, are our engineering graduates competent enough to meet the dynamic workplace requirements?

Though most engineering colleges provide students with good theoretical knowledge and placements, not all the students are appropriately skilled to remain employable. Let’s take an example from Welding, as a subject in the Engineering curriculum and or as an area of specialization in Welding Technology courses.

Knowledge of welding is integral to courses in Mechatronics Engineering, Mechanical Engineering, Paint Technology, Welding Technology, Construction Engineering, Automotive manufacturing, and others. What about the need to acquire welding skills through the practical application of knowledge? Is this also a mandatory component in the curriculum? How far have we taken care of the industry expectations in delivering practical training?

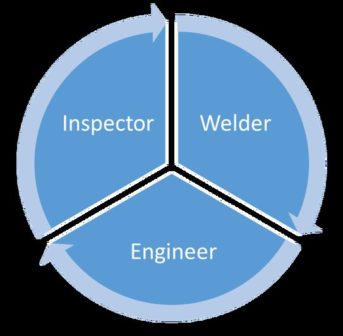

Workplace hierarchies are replaced by symbiotic relationships

Fast-changing hierarchies at the workplace demand engineers to have hands-on experience in using the tools and technologies. Today, the first job for an engineering graduate demands their agility in solving problems on the shop floor all by themselves. Hence, it’s a misnomer to believe that all engineers enter the industry as supervisors and production managers who don’t need to ‘dirty their hands’ performing manual tasks.

The workplace relationships become more symbiotic, which means, the engineer, the inspector, and the welder have to work together through continuous interaction and mutual exchange of knowledge. This makes process familiarity through hands-on experience in welding is a must! The engineers must have the ability to proactively demonstrate the solution by using the tools or rectify the defects to ensure quality. They will not be able to achieve this without undergoing the rigorous process of working with the latest welding tools before making a transition to the workplace.

The workplace relationships become more symbiotic, which means, the engineer, the inspector, and the welder have to work together through continuous interaction and mutual exchange of knowledge. This makes process familiarity through hands-on experience in welding is a must! The engineers must have the ability to proactively demonstrate the solution by using the tools or rectify the defects to ensure quality. They will not be able to achieve this without undergoing the rigorous process of working with the latest welding tools before making a transition to the workplace.

In fact, the engineering degree course in IIT Madras in the 1970s was a 5-year course that had the first two years entirely spent in the workshop.

In other words, we need to re-look at the hands-on training provided in the Engineering Colleges along with the curriculum for the practical sessions. Remember, in today’s industry scenario, there is absolutely no tolerance for mistakes, errors, and defects in welding, since more than 68% of permanent failures are linked to incorrect application of welding skills.

Why Simulator-based training for Welding in Engineering colleges is the need of the hour

Why Simulator-based training for Welding in Engineering colleges is the need of the hour

To meet this challenge, all the Engineering Colleges have to abide by the rule of practicing until one doesn’t make a mistake. However, achieving this goal through conventional training methods is highly debatable. This is because of the inherent shortcomings in the system that tilts heavily towards theoretical understanding and uses outdated training methodology.

It’s highly imperative to adopt technology-enabled training through simulators that replicate the real workplace issues and prepare the students to become productive from day one. Simulator-based welding training is not only a modern way to infuse technology into the Engineering curriculum but also an effective means of overcoming the limitations of the outdated notions of learning about welding.

Conventional training in welding skills

Given the short duration of time spent in the workshop in the current engineering curriculum, students trained entirely on actual welding equipment hardly get to know what they did right and what they did wrong as inputs leading to the output of the welded component. This is because welding machines do not provide any such data, nor as capable of measuring important hand skills like arc length, speed, weld angle, travel angle, etc.

How do we then provide this crucial input, within the few hours of welding practicals in the curriculum?

Simulator-based training in welding skills

Simulator-based training for welding in engineering colleges could drastically improve the teaching methods, effective training, and dexterity of the graduates. By using simulators in the welding practical sessions with the ability to measure and show feedback on how well the student is doing on these critical skill elements during practice, and also show them linkages between the input and output quality after each welding exercise, more knowledge and skill is transferred to the student in the allocated time.

Related Article: Skillveri fills manufacturing skill gaps with welding simulators Read More: https://nationalskillsnetwork.in/skillveri-welding-simulators/

Why simulator-based training for welding will work for Engineering Colleges

Through a simulator-based training in welding, students will learn the torch distance, travel/work angle, travel speed and welding path through live feedback of skill measurement and analyses of the quality output.

Simulator-integrated training is proven to achieve better and measurable quality in less time; to reduce defects in the actual job; help engineering students understand the skill and be better managers; deliver training at places that have space and time constraints. Ultimately it saves consumables, protects health, saves the environment and reduces emissions for training.

Training on simulators will make it more efficient with objective evaluation and on-time results. Engineering graduates will become productive from day one of their job, thereby saving Industries time and resources that go into training them again.

At the time when the relevance of the Engineering curriculum is being questioned by the industry, but welding graduates are highly sought after, it makes perfect sense to adopt the latest technologies to train the students. Investing in welding simulators could be the first step towards enhancing the employability of engineering graduates in India and abroad.

Guest Author: Sabarinath C Nair, Founder – CEO, Skillveri Training Solutions Pvt Ltd.

For more information and a demo of our simulators, please contact us – sales@skillveri.com

I want Information about welding simulator